Forged-Rolled Steel Bar Offers Best of Both Worlds

Ovako AB is completing a multimillion-dollar investment at two mills (Hofors and Hällefors) in Sweden to produce forged-rolled black bar. The company’s production and R&D teams have implemented...

Ovako AB is completing a multimillion-dollar investment at two mills (Hofors and Hällefors) in Sweden to produce forged-rolled black bar. The company’s production and R&D teams have implemented...

1. Weld the flange to the pipe and cool it to ambient temperature before installing the valve onto the flange. Otherwise the high temperatures generated by the weld can affect the performance of the resilient...

A ductile iron pipe is made of a kind of cast iron, carbon and silicon alloy, is an iron ore stone blast furnace smelting product. According to the different forms of carbon in pig iron, it can be...

Valves are used to control the flow of gases, liquids and granular solids. They come in many types, sizes, materials, pressures and temperature ratings, and means of actuation. Globe valves...

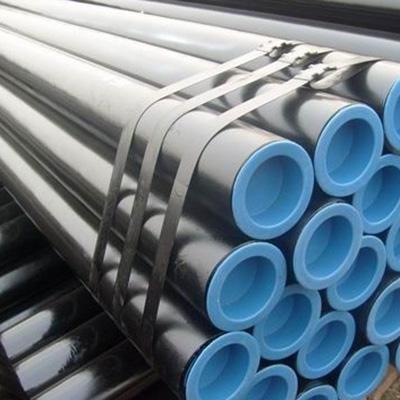

Steel pipes can be categorized into welded and seamless types. The following introduces several common steel pipe production methods. Seamless pipe Seamless...

Copper -- It has a moderate segregation tendency which when reaching a comparable content is detrimental to the thermal deformation process of steel. Copper has a negative impact on forging, but it does...

Carbon -- Carbon is an indispensable alloying element in steel for the formation of cementite (and other carbides), pearlite, spheroidite, bainite and Fe-C martensite. A microstructure composed of one...

Martensitic stainless steel has high hardenability and can be air-cooled and hardened. Because of that, when cold forging martensitic steels, especially those with high carbon steel, it is important to...

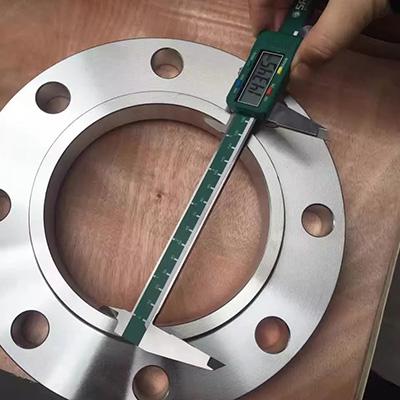

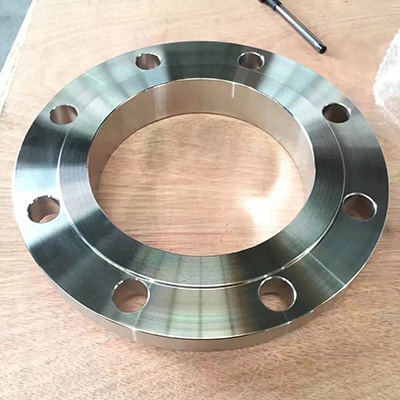

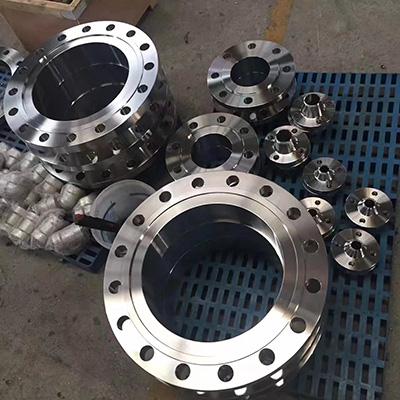

Flange assembly 1. Before assembling the flange, the flange surface, especially the sealing surface, must be cleaned. 2. When assembling slip-on flange, the pipe end should be inserted into two third...

Repairing the sealing surface is a large and important task because after long-term use, the sealing surface of the valve disc and the valve seat will wear and the tightness will be reduced. The main...

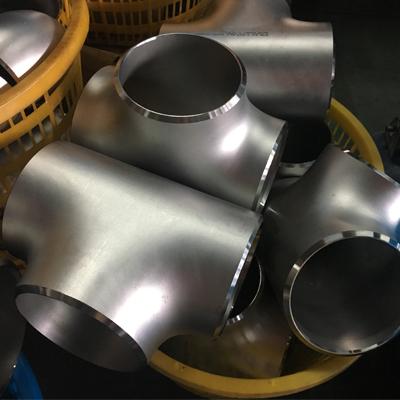

For stainless steel pipe fittings and flange manufacturers, it is necessary to take into account not only the production cost of flange and pipe fittings, but more importantly, the factors that can prevent...

According to the functions and uses of gate valves and butterfly valves, a gate valve has small flow resistance and good sealing performance. Because the disc of the gate valve is perpendicular to the...

Forging of slip-on flanges can be categorized into rotary forging, roll forging, cross-wedge rolling, rotary swaging, etc. based on the movement mode. For improving the utilization rate of materials,...

Sealing principle The two sealing faces of the screw press against the flange gasket and form a seal, but this also causes damage to the seal. So, in order to maintain the seal, the screw bolts, as well...

There are two problems may occur if the amount of grease is neglected when injecting. One is that the amount of grease is less than the required amount, and the abrasion of sealing surface is accelerated...

The production process of blind flange can be divided into three types: forging, casting and cutting. Cast flange and forged flange have a shape with accurate size, and advantages such as small workload,...

This is an analysis of causes of casting defects during the valve manufacturing process. Gas Bubbles These are small cavities that cause by residual gas during the metal solidification process. Their...

Welded steel pipes are also known as welded pipes, which can be divided into longitudinal welded pipe and spiral welded pipes according to the type of weld joint; or furnace butt weld pipes, electric...

The application scope of steel pipes is quite extensive with the development of this industry that they have branched out into not only gas or liquid transportation, but also associated products manufacturing...

China has made progress in reducing steel production capacity, which has led to increased efficiency and mismatch between supply and demand. In the first seven months of 2018, China cut 2.47 billion tons...